Prefab Home Options for Empty Nesters, Limited Mobility, and Off-Grid Living

Outline of the Article

This article maps a practical route through three highly requested prefab paths—downsizing for empty nesters, building for limited mobility, and living off-grid—so you can compare needs, timelines, and costs before you lift a hammer. We begin with a broad context for why prefab is gaining traction, focusing on reduced site disruption, predictable schedules, and well-controlled construction quality. Next, we dive into tailored design strategies for homeowners at distinct life stages and goals, then tie it all together with a concluding checklist to support confident decision-making.

The structure of the piece is intentionally layered:

– Introduction and context: What “prefab” really means, from modular to panelized systems; how factory-built precision can reduce waste and compress schedules.

– Empty nester priorities: Right-sizing floor plans, low-maintenance materials, and flexible spaces for guests or hobbies.

– Limited mobility features: Universal design dimensions, safe circulation, and durable, slip-resistant finishes.

– Off-grid kits: Envelope performance, solar and storage sizing, water systems, and realistic budgeting.

– Decision guide and conclusion: A quick synthesis translating preferences into an actionable plan.

Key comparisons will include:

– Space planning: one-story living vs. compact two-story footprints with a primary suite on the main level.

– Cost ranges: how kit prices relate to site work, transport, and regional labor variables; why “all-in” budgets differ widely.

– Performance data: common target R-values by climate, window performance metrics (U-factor, SHGC), and air-sealing benchmarks that influence comfort and bills.

– Accessibility metrics: 36 in doorways, 42 in hallways, a 60 in turning circle, low thresholds, and a 1:12 ramp slope.

– Off-grid energy rough-ins: 6–12 kW PV arrays for small homes; 10–30 kWh battery banks for overnight loads; and when a backup generator makes sense.

The tone remains clear-eyed and practical—no inflated promises—because successful prefab projects start with informed trade-offs. We also highlight timeline patterns: a typical sequence is 8–16 weeks of factory fabrication, 4–12 weeks of site work and inspections, with weather, permitting, and utility coordination shaping the schedule. Throughout, you’ll find small nudges for creative living: a window placed to catch morning light, a mudroom sized for muddy boots and a dog bed, or a porch that turns a small home into a big experience. If you want a guide that respects budgets and celebrates comfort, the next sections deliver.

Introduction and Context: Why Prefab Fits Today’s Living

Prefab is not a single product but a range of approaches—modular boxes assembled like building blocks, flat panel systems craned into place, and hybrid methods that combine a factory-built shell with local finishing. What unites them is controlled fabrication that can dial in consistent quality and reduce waste compared with fully site-built methods. By shifting much of the work under a roof with repeatable processes, projects often see more predictable timelines and fewer weather delays. This can translate into fewer change orders and an easier time coordinating trades, which is helpful whether you’re shrinking your footprint, making a home more accessible, or aiming for off-grid resilience.

Across use cases, the same core levers matter: a tight building envelope for comfort and energy efficiency; durable, low-maintenance materials; smart daylighting to reduce reliance on artificial lighting; and a floor plan tuned to real life rather than a catalog fantasy. For many households, right-sizing to around 600–1,200 square feet can optimize both construction and operating costs while still feeling generous when paired with outdoor rooms like porches and decks. And because many prefab systems are structurally precise, integrating high-performance windows, continuous insulation, and robust air-sealing becomes easier to execute consistently.

Budget clarity is central. A prefab kit or modular package cost typically excludes foundation, craning, site utilities, delivery distance, local labor, and permit fees. That’s why two homes with the same kit price may diverge in “all-in” costs by tens of thousands based on terrain, jurisdiction requirements, and finish choices. A realistic planning range some owners use is to treat the shell/package as perhaps half to two-thirds of their total budget, then refine that ratio after getting site-specific quotes. Timelines also hinge on early coordination:

– Confirm zoning, foundation type, and setbacks before design lock-in.

– Secure utility plans or off-grid alternatives early, especially transformers or well and septic testing windows.

– Sequence inspections and transport appointments to avoid idle days and rescheduling penalties.

Finally, quality of life matters as much as kilowatt-hours and square feet. Empty nesters can invest in quiet comfort and flexible hosting. Households prioritizing mobility can get factory-integrated blocking for future grab bars and accessible showers that feel spa-like rather than clinical. Off-grid enthusiasts can balance autonomy with redundancy, pairing solar and storage with a backup plan that respects seasonal variability. The sections that follow explore each path in detail.

Prefab Homes for Empty Nesters: Right-Sized, Low-Stress Living

When the last bedroom goes quiet, space starts to feel different. For many empty nesters, a prefab home is a thoughtful reset: fewer rooms to dust, more square feet dedicated to what you actually use, and a plan that puts comfort above unused formality. Single-level living is a common priority, not only for day-to-day ease but also for future accessibility. A sweet spot for many couples is 700–1,200 square feet with one primary suite, a flex room that doubles as a guest space or studio, and an open kitchen-living area that invites conversation without shouting across zones.

Design moves that deliver outsized value include a covered entry, a generous mudroom-laundry, and a kitchen with a practical work triangle. Place windows to borrow views and bounce daylight deep into rooms; better daylight can meaningfully reduce lighting use during shoulder seasons. Consider materials that age gracefully and demand little fuss:

– Durable siding such as fiber-cement or treated wood with factory finishes that simplify upkeep.

– Roofing with long service life, paired with robust gutters and leaf guards.

– Engineered flooring or sealed concrete that shrugs off sand and pet claws.

– Cabinet hardware and hinges designed for thousands of cycles without loosening.

Acoustics are an underrated luxury. Insulating interior partitions around bathrooms and the flex room keeps the main space calm while a guest naps or someone practices guitar. For mechanical systems, a modest heat pump sized to the actual load (not a rule-of-thumb oversize) helps maintain even temperatures and quiet operation. High-performance windows with low U-factors and appropriate solar heat gain coefficients for your climate also improve comfort around seating areas, so your favorite reading chair near the glass stays cozy in winter.

Budget basics for empty nesters tend to center on predictable operating costs and low maintenance. While kit or modular package prices vary widely by provider and region, owners commonly find that finishes and site work define the tail of the budget. Practical ranges might include:

– Shell or modular package: a broad span depending on size and spec.

– Site costs: excavation, foundation, utility connections, driveway, and landscaping, often a significant share of the total.

– Upgrades: triple-pane windows in cold climates, enhanced insulation, or a screened porch that turns a compact plan into a summer retreat.

Finally, think about lifestyle choreography. A porch aligned with sunrise invites quiet coffee; a storage wall in the flex room swallows seasonal gear; a small guest bath keeps visits relaxed. If you travel frequently, pair simple landscaping with timed irrigation and durable exterior finishes to minimize “vacation recovery” chores. The goal is a home that feels effortless—compact, comfortable, and ready for the hobbies and hosting that make this chapter lively.

Prefab Homes for Limited Mobility: Universal Design That Feels Natural

A home that supports limited mobility is not a collection of afterthoughts; it’s a coherent design language that makes circulation obvious, tasks easier, and rest truly restorative. Prefab can help by integrating accessibility into the factory stage where tolerances are tight and details repeat reliably. Start with zero-step entries at the primary door and from the garage or carport. Keep door thresholds as low as possible—ideally 1/4 in, or 1/2 in with a bevel where needed—and specify generous clearances: 36 in interior doors, 42 in hallways, and a 60 in turning radius in kitchens, bathrooms, and entries to allow comfortable maneuvering.

Bathroom planning is pivotal. Curb-free showers with linear drains reduce tripping hazards and simplify rolling or seated entry. Set the shower controls within easy reach at the opening to avoid reaching through water. Include continuous blocking in shower and toilet walls to allow future grab bar placement without demolition. Choose a slip-resistant tile with a wet dynamic coefficient of friction around 0.42 or higher under the relevant testing standard. Add a handheld shower on a vertical slide bar and a folding bench or a built-in seat. A contrasting floor tone helps define edges for those with low vision, while ample, glare-free task lighting keeps grooming comfortable.

The kitchen should combine reachability with workflow logic. Consider 34 in counter heights at a working section, pull-out shelves, D-shaped pulls, and full-extension drawers. Maintain a 48 in clear space in front of appliances, and leave knee space under at least one work surface. Induction cooktops reduce burn risk by keeping surrounding surfaces cooler. Side-opening wall ovens are easier to access from seated positions. Small details matter:

– Lever handles instead of knobs at doors and faucets.

– Rocker or large-paddle switches placed 36–44 in above finished floor.

– Outlets at 18–24 in above finished floor to reduce bending.

– Strong color contrast at stair edges and level changes, even in a single-story home with sunken living zones.

Ramps should target a 1:12 slope where possible, with landings every 30 ft and at turns. Handrails on both sides provide redundancy. For exterior paths, a firm, slip-resistant surface—compacted crushed stone with a stabilizer, textured concrete, or pavers with tight joints—helps wheels track straight and feet feel secure. Inside, avoid high-pile carpets; low-pile or resilient flooring reduces effort and snagging risk.

Prefab’s factory process offers subtle advantages: preinstalled backing for grab bars, consistent door rough openings, and careful thresholds that limit surprise lip heights. Mechanical systems can prioritize quiet, even airflow to reduce drafts and fatigue. Consider redundant lighting with motion sensors in halls and baths to reduce nighttime fumbling, and think ahead about backup power if medical devices are part of daily life. Most important, aim for dignity: accessibility that looks like thoughtful design, not a retrofit bandage, so the home welcomes everyone—today and for decades.

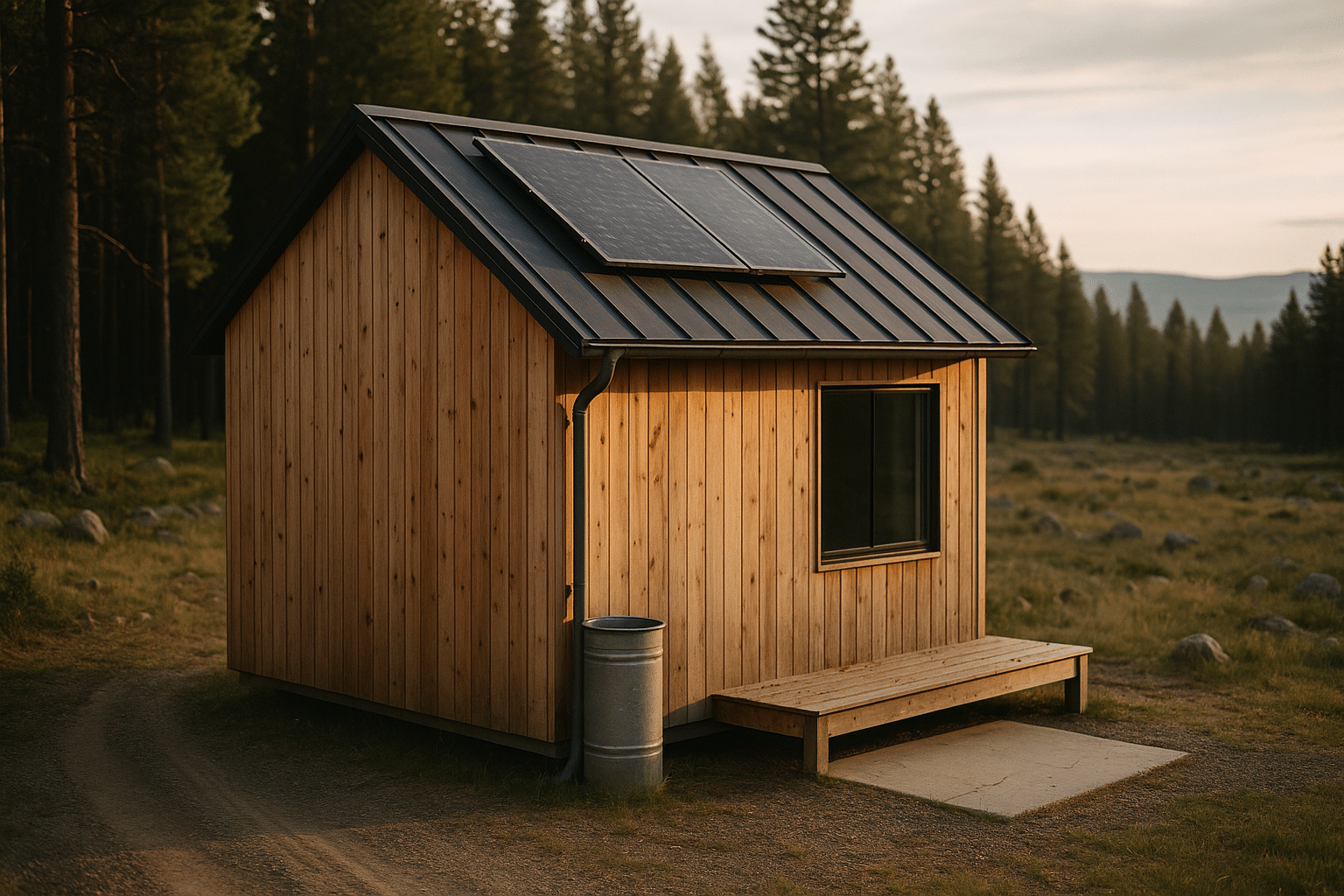

Off-Grid Prefab House Kits and a Practical Conclusion

Off-grid prefab kits appeal to those who want autonomy and a close relationship with place. The core equation pairs a well-insulated, airtight shell with right-sized energy systems, resilient water solutions, and simple maintenance. Begin with the envelope: target robust insulation (for example, roof assemblies reaching R-40 to R-60 in cold regions and walls from R-20 to R-30 or more, depending on climate and code), tight air-sealing (a blower door target of 3 air changes per hour at 50 Pascals or lower makes heating and cooling more predictable), and high-performance glazing tuned to orientation. Shade west windows aggressively, invite low-angle winter sun to the south where appropriate, and use overhangs or deciduous planting to keep summer gains in check.

Solar and storage planning hinges on loads. A compact home with efficient appliances, induction cooking, heat pump space conditioning, and heat pump water heating may land near a 6–12 kW photovoltaic array for typical daily use in many regions, paired with 10–30 kWh of battery storage to bridge evening peaks and short outages. In cloudy stretches or winter shoulder seasons, a backup generator can keep batteries in a healthy state of charge. To right-size, tally daily watt-hour consumption and consider:

– Peak draws (microwave plus well pump plus minisplit startup).

– Seasonal variation (short winter days vs. long summer production).

– Future additions (EV charging, workshop tools, greenhouse fans).

Water systems are site-specific. Where legal and practical, rainwater harvesting paired with a 3,000–10,000 gallon cistern and multi-stage filtration can complement a well or even serve as the primary source. Greywater reuse for landscape irrigation can cut overall demand if local codes allow. For wastewater, options range from conventional septic to advanced treatment units; composting systems may fit remote parcels with shallow soils, but confirm permitting early. Ventilation is critical in tight homes: a heat or energy recovery ventilator maintains air quality with minimal energy penalty, and a simple filtration setup reduces dust from wood stoves if you add one for ambiance and backup heat.

Budgeting for off-grid adds a distinct layer. A kit shell may be one line item, but site work and systems often shape the final tally. As a rough planning mindset, owners sometimes earmark an additional five figures for the energy package alone (solar, batteries, balance-of-system components), recognizing that storage capacity and local installation rates can swing this widely. Logistics matter: can a delivery truck access the site without winching; will a crane need a temporary roadbed; how will you handle snow or seasonal mud during set?

Maintenance brings autonomy to life. Brush back vegetation to lower wildfire risk; check roof fasteners after the first storm season; rinse panels after dusty winds; service filters on the ventilation system; test backup power quarterly. Small, regular tasks preserve performance and reduce surprise costs. And weather will still do what weather does—design in forgiveness with overhangs, robust flashing, and materials that don’t mind a little grit.

Conclusion: Choosing the Right Prefab Path

If you’re downsizing, start with a one-level plan, low-maintenance finishes, and a porch that multiplies living space without adding heated square feet. If mobility is in focus, let universal design lead—wide clearances, curb-free showers, lever handles, bright contrasts—and lean on prefab’s precision for factory-integrated support. If off-grid calls your name, treat the envelope as the first energy system, then size solar, storage, and water solutions to real loads and local climate. In every case, clarify site conditions, permitting steps, and delivery logistics before you fall in love with a floor plan. A short, honest checklist—needs, budget range, timeline, and maintenance appetite—turns a wish into a home that works day one and adapts gracefully as life changes.