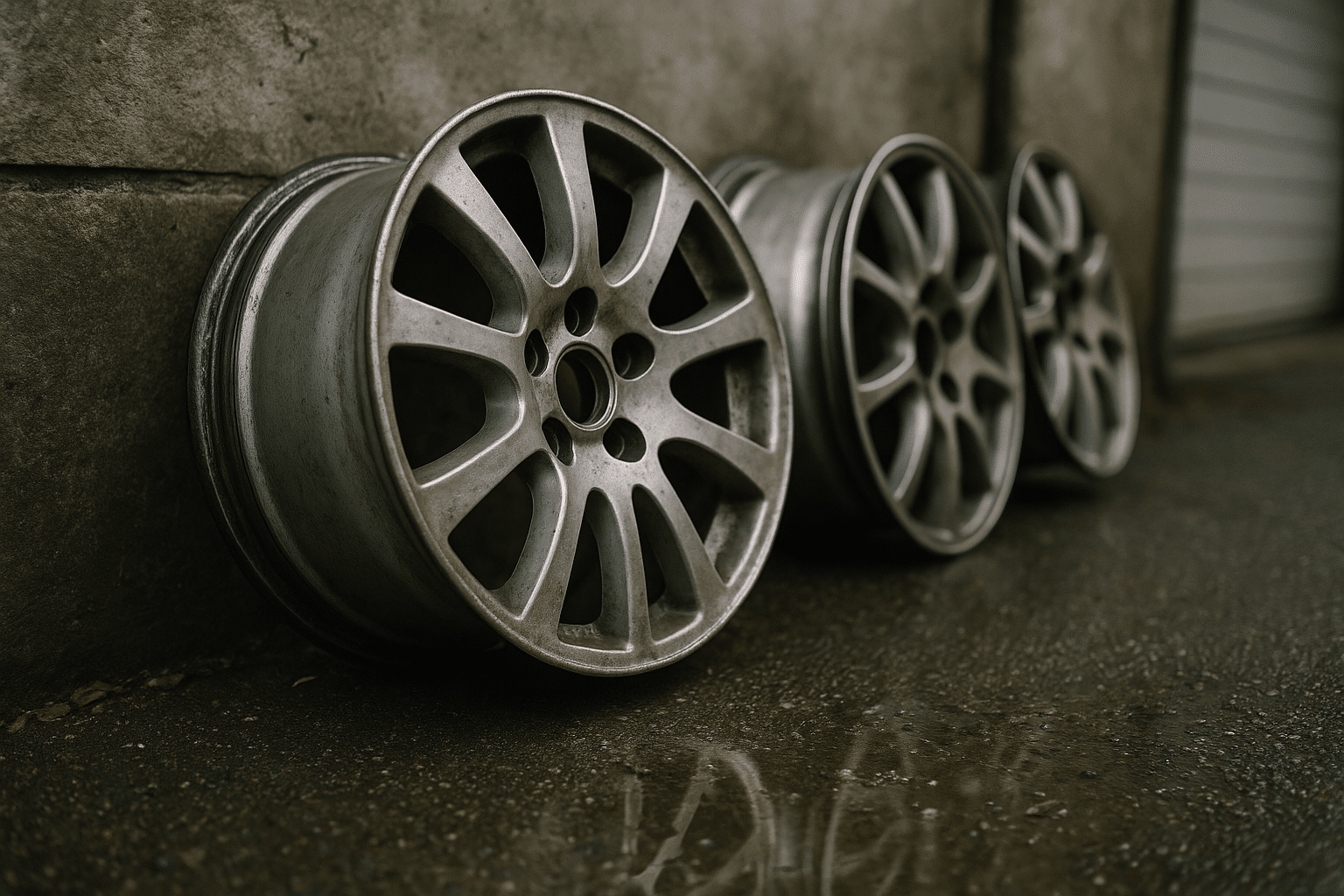

Used Rims: A Practical Guide to a Smart Purchase

Outline:

– Rim basics: materials, measurements, and the fitment terms that matter.

– Inspection checklist: how to evaluate condition and detect red flags.

– Safety and legality: clearance, load ratings, fasteners, and regulations.

– Pricing and buying: marketplaces, fair value, and negotiation tactics.

– Refurbish and care: repair limits, finishing options, and long-term upkeep.

Rim Basics: Materials, Measurements, and Fitment Fundamentals

Understanding the language of rims turns confusing listings into clear opportunities. Start with materials. Steel rims are durable, economical, and typically heavier, which can add unsprung mass but shrug off everyday abuse. Alloy rims (commonly aluminum-based) are lighter for the same size, often improving ride quality and steering response while offering more complex designs. Typical weight examples for 16-inch wheels: steel roughly 20–25 lb, alloy often 15–20 lb, though designs and widths vary. Heavier-duty vehicles may demand stronger, heavier constructions; light city commuters can benefit from modest weight reductions via alloys.

Fitment is where the puzzle pieces must align. You’ll encounter a handful of measurements you cannot ignore:

– Diameter and width: e.g., 17×7.5 means 17 inches in diameter and 7.5 inches wide.

– Bolt pattern: expressed as number of lugs by circle diameter (e.g., 5×114.3). It must match the hub exactly.

– Offset (ET): distance from the wheel’s mounting surface to centerline, measured in millimeters. Positive offset tucks the wheel inward; lower offset pushes it outward.

– Center bore: the hole that fits over the hub. Matching or larger is workable; larger bores typically need hub-centric rings.

– Load rating: the wheel’s rated capacity, which should meet or exceed the vehicle’s requirement.

Offset deserves special attention. Changing offset alters scrub radius and can influence steering feel, bearing loads, and fender clearance. Many passenger cars run moderate positive offsets (often +35 to +50 mm), but you must confirm what your vehicle expects. Even a 5–10 mm change can affect inner-clearance to struts and outer lip poke. Brake caliper shape also matters; sculpted spokes may clear big calipers that flat designs won’t.

Tires complete the package. If you’re upsizing diameter, a lower-profile tire usually preserves overall rolling diameter. That helps keep speedometer error minimal and maintains gearing feel. Pay attention to:

– Recommended tire width range for the wheel’s width.

– Whether your vehicle uses direct tire pressure sensors and if the wheel accepts them.

– Valve stem type and seat shape.

Finally, cross-check everything against vehicle specifications. A rim that “almost fits” usually becomes a headache. If you align material choice, bolt pattern, offset, width, center bore, and load rating, you’re already ahead of most shoppers—and on the path to a safe, satisfying purchase.

How to Inspect a Used Rim: A Step-by-Step Checklist

A careful inspection can turn a gamble into a calculated win. Set the wheel on a flat surface with good natural light and take your time. You’re looking for straightness, structural soundness, and serviceable finish. Bring a small flashlight, a straightedge or ruler, and if possible a dial indicator or a makeshift setup that reveals wobble.

Begin with the barrel and lips. Stand the rim upright and spin it gently. Watch the inner and outer lips for lateral movement—wobbles hint at bends. Many passenger vehicles specify runout limits in the neighborhood of roughly 0.030–0.050 inch (0.76–1.27 mm), but always defer to the vehicle or wheel maker’s guidance. A minor flat spot at the outer lip can sometimes be professionally straightened; a sharp kink or ripple near a spoke is more serious.

Scan for cracks. Hairline fractures often hide:

– At the base of spokes where stress concentrates.

– On the inner barrel, especially after pothole strikes.

– Around the bead seat where the tire seals.

If you see a crack, assume replacement is the safer path. Welded repairs on cast rims are controversial; many technicians advise avoiding wheels with any crack history, particularly near critical areas.

Check the bead seats and rim flanges. Deep gouges or heavy corrosion along the bead seat can cause slow leaks. Light surface oxidation is common on older rims, but flaky, pitted areas should raise concern. Look closely at lug holes: oval-shaped wear suggests over-torquing or mismatched lug seats. The lug seat style must match your fasteners (common seats include conical and ball). Mismatch can cause loosening and vibration.

Evaluate the face and finish. Curb rash, peeling clearcoat, or clouded paint are cosmetic; they can often be refurbished at a predictable cost. Distinguish aesthetics from structure:

– Cosmetic rash: scuffs along the outer lip, usually repairable.

– Bends: lateral hop when spun, may be fixable if minor and away from spokes.

– Cracks: no-go warning sign.

If the wheel has a tire mounted, ask for an air-leak test. A soapy-water spray around the bead and valve can reveal bubbles. Also inspect the inside barrel for evidence of previous repairs, welds, or filler. Finally, ask for proof of size, offset, and load rating—these are typically cast or stamped on the back. A seller willing to provide clear photos of the front face, rear barrel, inner lip, markings, and a spin test video is more likely to be offering a solid wheel.

Fitment, Safety, and Legal Considerations You Should Not Ignore

Fitment is more than a number; it’s the relationship between your wheel, tire, and vehicle dynamics. Start with clearance. Inner clearance affects struts and control arms; outer clearance risks fender rub under compression and steering lock. A rim that is 8 mm wider adds 4 mm per side; combine that with offset changes and you can estimate how much inward or outward movement you’re adding. Even small changes can be felt in steering weight and road feel.

Brake caliper clearance is frequently overlooked. Some spoke profiles arc outward and clear big calipers; flatter, blockier designs may collide. When in doubt, use a template or test-fit with no tire mounted. Spin the hub slowly and watch for interference. If you need spacers to clear brakes, choose quality units and understand that spacers effectively reduce offset, which can influence bearing loads and fender clearance.

Safety hinges on proper hardware. Fastener seat type must match the wheel’s seat profile. Conical-seat lugs in ball-seat wheels (or vice versa) reduce contact area, leading to loosening. Hub-centric wheels center on the hub; lug-centric wheels rely on the fasteners. If the center bore is larger than your hub, consider hub-centric rings to prevent vibration. Torque fasteners to manufacturer specifications using a calibrated wrench and recheck after the first 50–100 miles of driving.

Load rating and construction matter, especially for heavier vehicles or those that carry frequent cargo. The wheel’s load capacity should meet or exceed your vehicle’s requirement. This rating is not a suggestion; it’s a safety limit tested under prescribed conditions. Exceeding it can accelerate fatigue and increase failure risk on rough roads.

Regulations vary by region, but common themes include prohibiting tire tread from protruding excessively beyond the fender and ensuring the vehicle remains roadworthy. Keep a few points in mind:

– Excessive poke can spray debris and attract attention from inspectors.

– Speedometer and odometer readings are primarily affected by overall tire diameter, not just rim diameter; keep total rolling diameter close to original.

– Winter conditions reward smaller diameters with taller sidewalls for better impact resilience and potentially improved traction.

Finally, consider sensor compatibility. If your vehicle uses direct tire pressure sensors, check that the wheel accepts the correct valve hole size and sensor mount type. Plan for new valve stems or sensor service kits during mounting. Good fitment respects the mechanical design of your vehicle, preserves handling, and keeps you on the right side of local rules.

Pricing, Places to Buy, and Negotiation Tactics

Used rims live in a busy marketplace, and price tends to reflect size, material, condition, and demand. A single used steel wheel in common sizes might list in the rough range of $25–$70, while a comparable alloy can range from about $80–$250 per wheel depending on diameter, width, and finish. Large-diameter, lightweight designs or rare fitments typically command more. A cosmetically worn but structurally straight wheel is often a smart buy if refurbishing costs stay predictable.

Where to shop:

– Local tire shops that take trade-ins or keep take-off wheels.

– Automotive recyclers and salvage yards with inventory tags and stamping photos.

– Reputable online marketplaces and local classifieds with detailed listings.

– Enthusiast forums where sellers know fitment details and provide runout videos.

Assess listings by their transparency. Ideal postings include clear images of the front face, rear barrel, inner and outer lips, lug seats, and all cast or stamped markings. Ask for a short clip of the wheel spun on a makeshift hub or balancer to visualize runout. Inquire about any prior repairs; welded spokes or bead seats are signals to pass. Confirm whether valve stems, caps, or hub-centric rings are included.

Factor hidden costs into your comparison:

– Shipping and packaging (proper padding, face protection, double boxing for larger diameters).

– Mounting, balancing, and potential sensor service kits.

– Cosmetic repair: light curb rash often $50–$100 per wheel; minor straightening often $80–$150; full refinishing varies with finish and region.

– New fasteners if seat style or thread length differs.

Negotiation favors prepared buyers. Reference comparable local sales rather than distant outliers, and politely explain deductions for defects you will need to address. Consider bundle offers for sets, and propose meeting at a tire shop for a quick inspection. If a seller offers a short return window, that signals confidence; confirm terms in writing within the platform’s messaging system. When purchasing remotely, use payment methods with buyer protection where available. By anchoring your offer in objective details—documented condition, refurbishment needs, and shipping—your negotiation feels fair and often lands you a solid value.

Refurbishing, Care, and Long-Term Ownership Tips

A used rim’s second life depends on smart refurbishment and gentle habits. Start by deciding what is worth repairing. Cosmetic curb rash and light lip bends away from spokes are commonly corrected by reputable shops. Deep gouges near the bead seat, heat discoloration from heavy welding, or cracks at spoke roots are reasons to move on rather than invest. Many technicians discourage using repaired cracked cast wheels, especially in critical areas, because the risk profile changes in ways you cannot easily evaluate.

Finishing options influence cost, durability, and appearance. Painted finishes are versatile and usually the most affordable to touch up. Powder coating creates a uniform, durable surface that resists chips and corrosion when properly prepped; it requires stripping and careful masking of mating surfaces. Clear-coated bare alloy can look refined but needs routine care to prevent filiform corrosion. Expect professional cosmetic repairs to vary by region and complexity; get itemized quotes so you can compare apples to apples.

Daily care pays dividends:

– Wash with pH-balanced soap and gentle brushes; avoid harsh acids on bare or damaged finishes.

– Remove brake dust early; it’s abrasive and can etch coatings when left to bake.

– Apply a wheel sealant or wax to make future cleanings easier and slow contamination buildup.

Mounting and installation are a chance to get details right. Use new valve stems or service kits for pressure sensors. Verify that hub-centric rings fit snugly and that lug seats match fasteners. Tighten lugs in a star pattern to the vehicle’s specified torque, then recheck after some miles. Balance the assembly carefully; if you feel persistent vibration, a road-force balance can diagnose stiff spots or subtle roundness issues.

Storage is simple but often neglected. Clean and dry the rims thoroughly, then store in a cool, dry place. If tires are mounted, stack horizontally with face protectors or store vertically on a rack to reduce sidewall stress. For seasonal sets, label position and rotation direction to streamline swaps. During ownership, inspect the wheels every few months for new chips, developing corrosion, or slow leaks. Addressing small problems early avoids bigger bills later.

Treat used rims like any precision component: refurbish wisely, maintain regularly, and respect manufacturer limits. Do that, and your purchase delivers long service with fewer surprises.