Why Your Car’s Clear Coat Peels: Causes, Fix Options, and Prevention Tips

Outline:

– Section 1: How clear coat is built into modern paint systems and the science behind peeling

– Section 2: Diagnosing the severity—tests, signs, and when damage is still reversible

– Section 3: DIY pathways—from cosmetic stopgaps to proper spot repair and blending

– Section 4: Professional solutions—repair options, fair costs, timelines, and questions to ask

– Section 5: Prevention and long-term care (Conclusion)—habits, schedules, and realistic protection

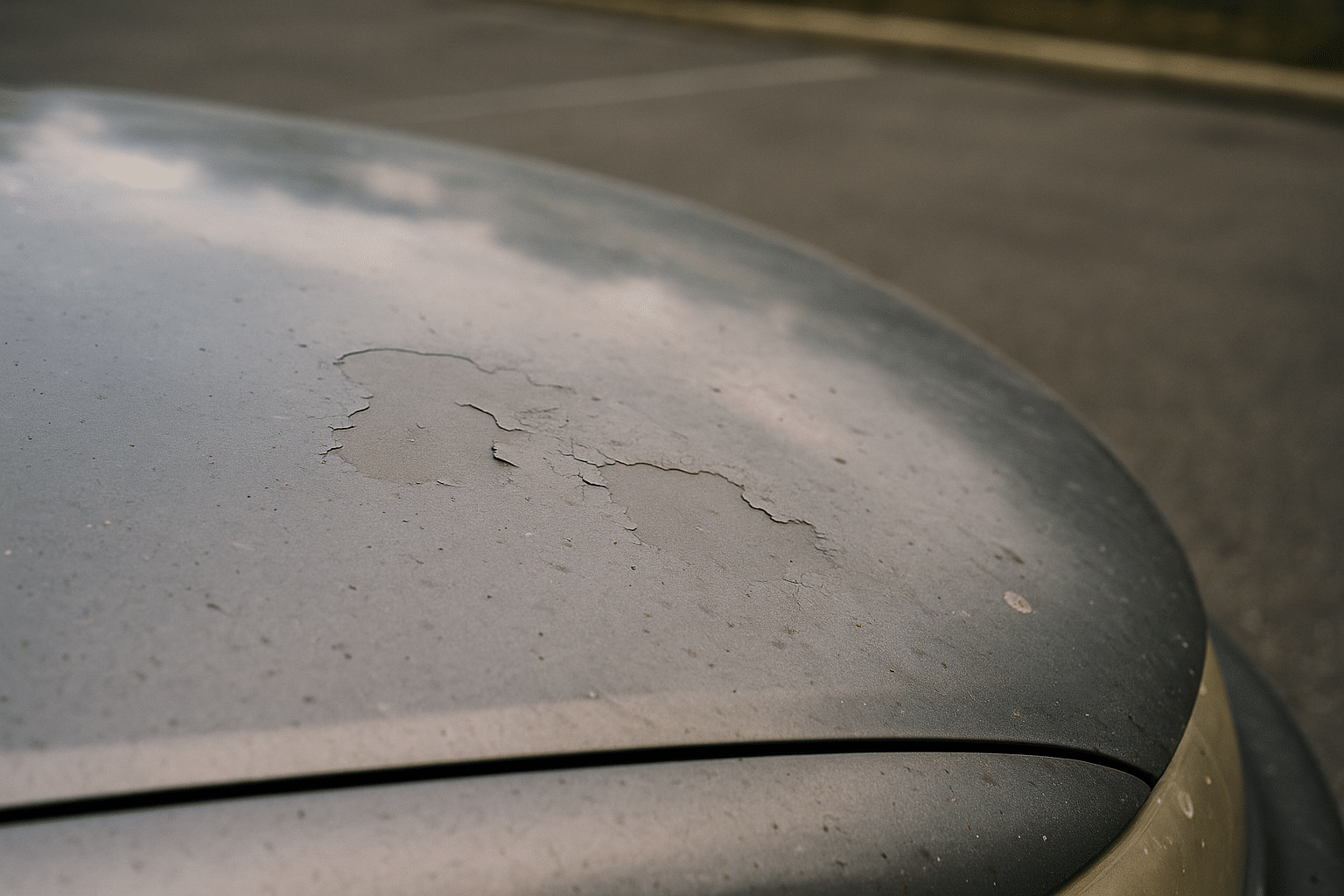

Introduction: Clear coat is the transparent armor of your car’s paint, the thin film that gives depth, gloss, and a crucial barrier against sun and weather. When it starts to haze, flake, or lift, you’re seeing a bond fail between layers, and each week of exposure can widen the damage. Understanding why it peels helps you choose the right fix—whether that’s a small-area repair or a professional refinish—and build habits that slow aging. The goal is simple: restore what you can today and protect it better tomorrow.

How Clear Coat Works and Why It Peels

Modern automotive paint is a layered system: a treated substrate (metal or plastic), a primer that promotes adhesion and corrosion resistance, a basecoat that supplies color and effect, and a clear coat that seals the stack, adds gloss, and provides UV protection. While total paint thickness often lands near 100–180 microns, the clear layer is usually only about 30–60 microns. That means the “window” protecting your color is thinner than a human hair, yet it absorbs the brunt of sunlight, temperature swings, water, road film, and chemical fallout. Over years, its polymers oxidize, UV absorbers deplete, and the interface to the basecoat can weaken—eventually leading to delamination (peeling).

Common triggers for failure include the environment and maintenance choices. High UV index regions accelerate photodegradation; summer panels can exceed 60°C on a dark finish, expanding and contracting daily. Acidic deposits (bird droppings, bug remains, tree sap) etch and swell the film if not removed promptly. Aggressive cleaners, strong solvents, and frequent abrasion from dirty wash media thin the top layer. Add in stone chips, prior sanding scratches, or a marginal past respray with poor prep, and the clear’s bond becomes a patchwork of stress points.

Leading culprits, in brief:

– UV and heat: Deplete stabilizers and embrittle resin, inviting micro-cracks.

– Chemical exposure: Etching and swelling that distorts the interface.

– Mechanical abrasion: Improper washing and harsh polishing reduce thickness.

– Poor refinishing: Insufficient surface prep, contamination, or wrong flash times undermine adhesion.

– Moisture intrusion: Water enters through chips and edges, lifting the film like a sticker.

Peeling often starts at edges, roof/hood horizontal panels, and stone-chipped areas—places with high sun load or direct impact. Early symptoms appear as dullness and faint “crow’s feet” in reflections. As micro-cracks network, sections lift and flake, exposing matte basecoat that stains easily. Once the clear is gone, the color layer is defenseless; repair urgency increases because every wash, sun day, and rain cycle can worsen the scar.

Diagnosing the Damage: Stages and Tests You Can Do at Home

Not all dull paint is a failing clear coat. Oxidation can make a finish look flat and chalky yet still be salvageable with polishing, while true delamination means the top layer is separating from the basecoat. Before you buy products or book a respray, take a methodical look. The goal is to distinguish cosmetic haze from structural failure and to map where each stage lives on the car, panel by panel.

Try these practical observations:

– Visual scan in indirect daylight: Haze with uniform swirl marks may be oxidation; jagged islands with defined edges suggest peeling.

– Fingernail edge test: If you can catch an edge where the finish has lifted, that’s clear failure; do not pick, just note the boundary.

– Water behavior: Oxidized clear may still bead after a wash if sealants are present; exposed basecoat tends to soak water and darken unevenly.

– Tape reveal: Place painter’s tape across a suspected boundary and pull gently; if flakes appear at the tape line, delamination is likely.

– Micro-crack patterns: “Crow’s feet” or a milky, spider-web look across sun-baked areas signal UV-weakened resin approaching failure.

You can also use simple tools. A consumer paint thickness gauge can show irregular readings: thinner spots on horizontal panels or sudden drops where sanding/previous repairs occurred. A bright LED at a low angle enhances surface texture; healthy clear reflects tightly, while compromised areas scatter light and show tiny fractures. A wipedown with a mild panel cleaner (or diluted isopropyl alcohol) temporarily removes fillers that mask defects, revealing the true surface.

Think in stages:

– Stage 1: Loss of gloss, faint haze, intact film. Often correctable with gentle polishing and protection.

– Stage 2: Early micro-cracking or faint edge lift, typically localized. Spot repair may be viable if prep is careful.

– Stage 3: Visible peeling islands and exposed color. DIY cosmetics can only hide contrast; durable fix usually requires refinishing the affected panel.

– Stage 4: Widespread failure across multiple panels. A comprehensive repaint is the realistic route.

Speed matters. Once color is exposed, UV and water can stain or fade pigments, making later color matching more difficult. Document each panel with photos and notes; this helps when discussing options with a shop and keeps DIY efforts focused where they have the most chance of success.

DIY Fixes That Work: Spot Repairs, Blending, and Temporary Cosmetic Improvements

DIY can deliver value when the damage is localized and the surrounding clear is still sound. The tough truth: rubbing compound will not glue lifting film back down, and no wipe-on product can rebuild missing clear to factory thickness. But you can improve appearance, slow progression, and in some cases execute a respectable spot repair that blends to an edge, buying years of acceptable looks on a daily driver.

For purely cosmetic uplift on intact but dull clear, think least aggressive first:

– Thorough wash and decontamination: Remove bonded grime with clay or a synthetic alternative to restore surface feel.

– Light polish: A fine finishing polish can restore clarity without excessive material removal.

– Protection: Apply a quality sealant or coating topper that includes UV absorbers; reapply on schedule, as these layers are sacrificial.

For small areas with early edge lift, a careful spot repair is possible:

– Mask and protect: Define a repair zone that extends into healthy clear; isolate trim and adjacent panels.

– Feather the edge: Wet-sand the lifted boundary with fine grits (e.g., 800–1500) until the transition feels smooth under a gloved fingertip.

– Surface prep: Clean thoroughly to remove residue and oils; dust or silicone contamination will ruin adhesion.

– Apply clear in light, even passes: Allow proper flash between coats and avoid heavy, wet passes that can solvent-pop.

– Level and refine: After full cure, wet-sand high spots with very fine grits (e.g., 2000–3000) and refine by polishing to recover gloss.

Key pitfalls to avoid:

– Chasing huge failure zones; large patches rarely blend invisibly at home and may telegraph edges.

– Skipping feathering; a harsh ridge will stand out when the sun hits it.

– Rushing cure times; premature sanding can gum the surface and dull the finish.

– Ignoring safety; appropriate gloves, eye protection, and respiratory measures are important when spraying or sanding.

Costs vary with scope. A DIY cosmetic refresh (wash, decon, polish, protect) might require modest materials and a weekend. A localized spot repair calls for sandpaper assortments, masking supplies, and a compatible clear; plan for multiple practice panels if you’re new to spraying. Expectations matter: under garage lighting, a well-executed blend can look strong, while in harsh noon sun you may still see a halo. Think of DIY as a smart triage—restore clarity where possible, stabilize edges, and delay the need for larger work.

Professional Solutions: Options, Costs, and What to Ask

When peeling stretches across a hood, roof, or multiple panels, the durable solution is typically refinishing by a qualified shop. A proper repair involves removing compromised clear, addressing any basecoat issues, laying new color as needed, and applying fresh clear with even film build. Professional facilities bring controlled booths, calibrated spray equipment, color-matching systems, and process discipline that is hard to replicate at home over larger areas.

Common pathways and typical ranges (which vary by region and vehicle size):

– Single-panel respray (e.g., roof or hood): Often a few hundred to over a thousand depending on prep complexity and blending.

– Adjacent-panel blends: Edges are blended onto neighboring panels to hide transitions, adding labor but improving visual continuity.

– Multi-panel or full repaint: From several thousand upward, influenced by number of panels, color type (solid vs metallic/pearl), and level of disassembly.

What to look for in a shop:

– Transparent estimating: A written scope that details substrate prep, corrosion checks, primer type, sealer use, basecoat steps, and clear application.

– Environment control: Dedicated spray booth with filtration that reduces dust nibs and ensures consistent curing.

– Color verification: Spray-out cards and sun checks to confirm match under different lighting.

– Quality assurances: Clear communication on film build targets, blending strategy, and aftercare instructions, plus a meaningful workmanship warranty.

Questions worth asking:

– How will you handle existing chips or previous repair edges to prevent future lift?

– Will you remove trim and hardware or mask in place, and why?

– What curing time do you recommend before washing, polishing, or applying protective films?

– How do you address plastic panels versus metal panels to account for different flex characteristics?

Timing and logistics matter. A single-panel job may be a one- to two-day turnaround, while multi-panel work can take a week or more to allow proper prep and cure. If you’re considering alternatives, vinyl wraps can hide uniform oxidation but do not adhere reliably over peeling paint; the failing substrate will telegraph through. Paint protection film and ceramic-based topcoats are add-ons after a healthy refinish, serving as sacrificial barriers against chips and UV, not band-aids for active delamination. A thoughtful conversation with a reputable shop—paired with realistic expectations—leads to results that age gracefully.

Prevention and Long-Term Care: Protecting Your Finish (Conclusion)

Once you’ve stabilized or repaired your finish, the priority shifts to slowing the clock. Prevention is less dramatic than repairs, but the quiet routines pay dividends every season. Think of your clear coat like sunscreen for the color beneath: it needs shade when possible, gentle cleaning to stay transparent, and replenished protection that absorbs what the sun throws at it.

Build a simple care plan:

– Parking strategy: Favor covered or shaded spots. Horizontal panels see the heaviest UV load; even partial shade reduces thermal swings and photodegradation.

– Wash rhythm: A pH-neutral shampoo, soft wash media, and two-bucket or contact-minimizing methods cut abrasion. Rinse off bird droppings and bug residue promptly to avoid etching.

– Decontamination cadence: Seasonal removal of bonded contaminants keeps the film slick and less likely to trap grime that bakes into the surface.

– Protection layers: Reapply a UV-focused sealant every few months, or maintain a coating with compatible toppers. These sacrificial films are not armor, but they meaningfully reduce exposure.

– Gentle corrections: Reserve polishing for when clarity drops; use fine abrasives and measure progress often to preserve film thickness.

Habits to avoid:

– Harsh solvents and strong alkaline cleaners for routine washes; they strip protection and can dry the clear.

– Dirty sponges and stiff brushes; they grind grit into the film and accelerate thinning.

– Ignoring chips; seal or repair them promptly to block moisture and stop underfilm creep.

For owners in high-UV climates or coastal areas, consider shorter intervals between protective applications and more frequent inspections of roof and hood. If a vehicle lives outdoors, lightweight covers can help, provided they’re clean and soft-lined to prevent friction marks. After professional refinishing, follow the shop’s cure guidance before applying any protection; early sealing can trap solvents that need time to outgas.

In short, your strategy has two halves: address failure honestly—DIY for small, contained issues and professional help when the film is broadly compromised—and then adopt a maintenance rhythm that respects how thin and vital the clear layer is. With mindful care, the finish stays vibrant longer, repairs last, and the next owner (even if it’s your future self) will thank you for a car that still turns heads for the right reasons.